4500BPH 4 cavity beverage bottle Energy-saving Fully Automatic PET Blow Molding Machine

4500BPH 4 cavity beverage bottle Energy-saving Fully Automatic PET Blow Molding Machine

BORG Machinery focus PET Blow Molding Machine for more than 10 years.

4 cavity beverage bottle Fully Automatic PET Blow Molding Machine is standard,fully servo motor,up to 2liter,6000 bottles per hour,based on 500ml 17g round bottle.

Energy-saving,well specified PET Blow Molding Machine for beverage bottle,cooking oil bottle,detergent bottle,cosmetic bottle,shampoo bottle,etc.

1.Cooperated Brand

2.MAIN COMPONENTS

Private server host.

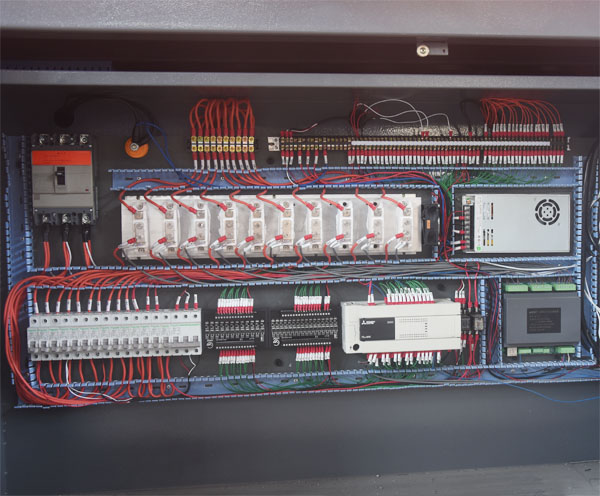

PLC control Brand: Mitsubishi Option Brand: Siemens

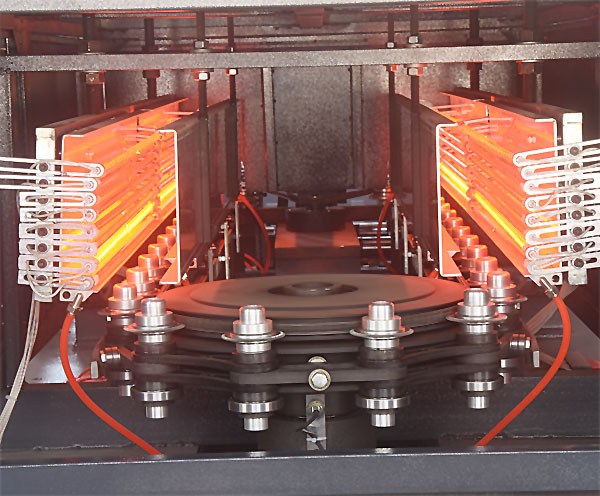

Infrared heating lamp tube Ruby Lamp

Central Processor.

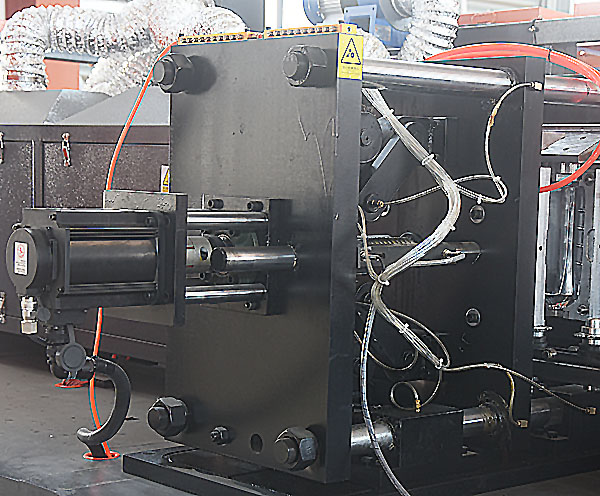

Mold lock.--Servo motor system

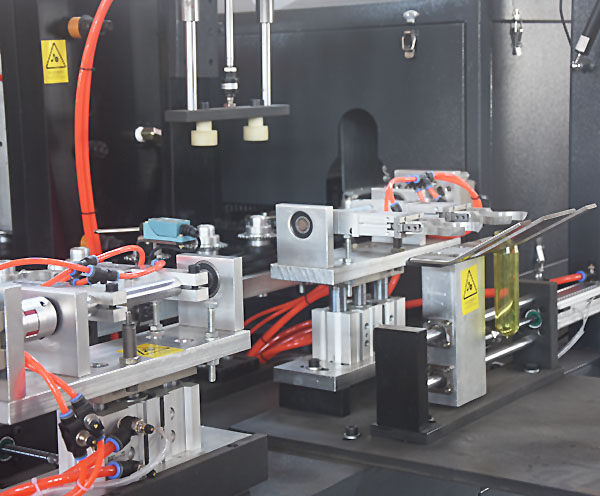

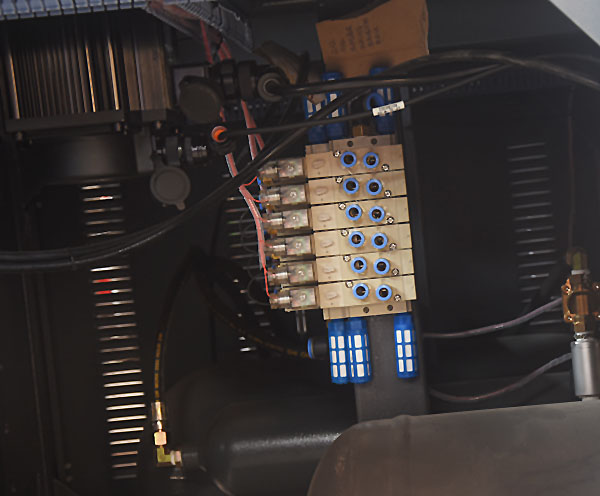

Cylinder MSC

Flip the cylinder,festo...

Blowing vale Fisto..

Product introduction

The Energy-saving automatic bottle blowing machine adopts novel and innovative modular design structure and linear full-automatic down-rotating up-bottle blank structure, with fast up-bottle blank speed and infrared lamp heating elements. Pneumatic components are imported well-known brands to ensure stable operation of equipment.

The automatic bottle blowing machine adopts novel and innovative modular design structure and linear full-automatic down-rotating up-bottle blank structure, with fast up-bottle blank speed and infrared lamp heating elements. Pneumatic components are imported well-known brands to ensure stable operation of equipment.4 cavity automatic PET stretch blowing machine ,stable output of 6000 bottles per hour, especially suitable for mineral water, beverage bottles.

Reference parameter

| Model | BG-2000-4 | |

| cavity | 4 | |

| Theory output | 7000 | |

| Bottle type specification | Max.volume | 2L |

| Bottle mouth maximum overall diameter | 28-38mm | |

| Bottle biggest diameter | 105mm | |

| Bottle maximum height | 330mm | |

| Light tube quantity | 32pcs | |

| Light tube power | 1.5KW | |

| Power specification | Maximum heating power | 48KW |

| All electric machine installation | 52KW | |

| Actual consumption | 40%–70% | |

| Work pressure | 7-9kg/cm2 | |

| Air pressure specification | Low-pressure gas consumption | 1000L/min |

| Blow bottle pressure | 25-35kg/cm2 | |

| Higher -pressure gas consumption | 3000Ltr/min | |

| Work pressure | 5-6 kg/cm2 | |

| Temperature range | 10℃ | |

| Consumption | 8000kcal/hr | |

| Forzen water flow | 138L/min | |

| Machine specification | Machine size | 4.1×1.6×1.9 |

| Machine weight | 3.9 ton |